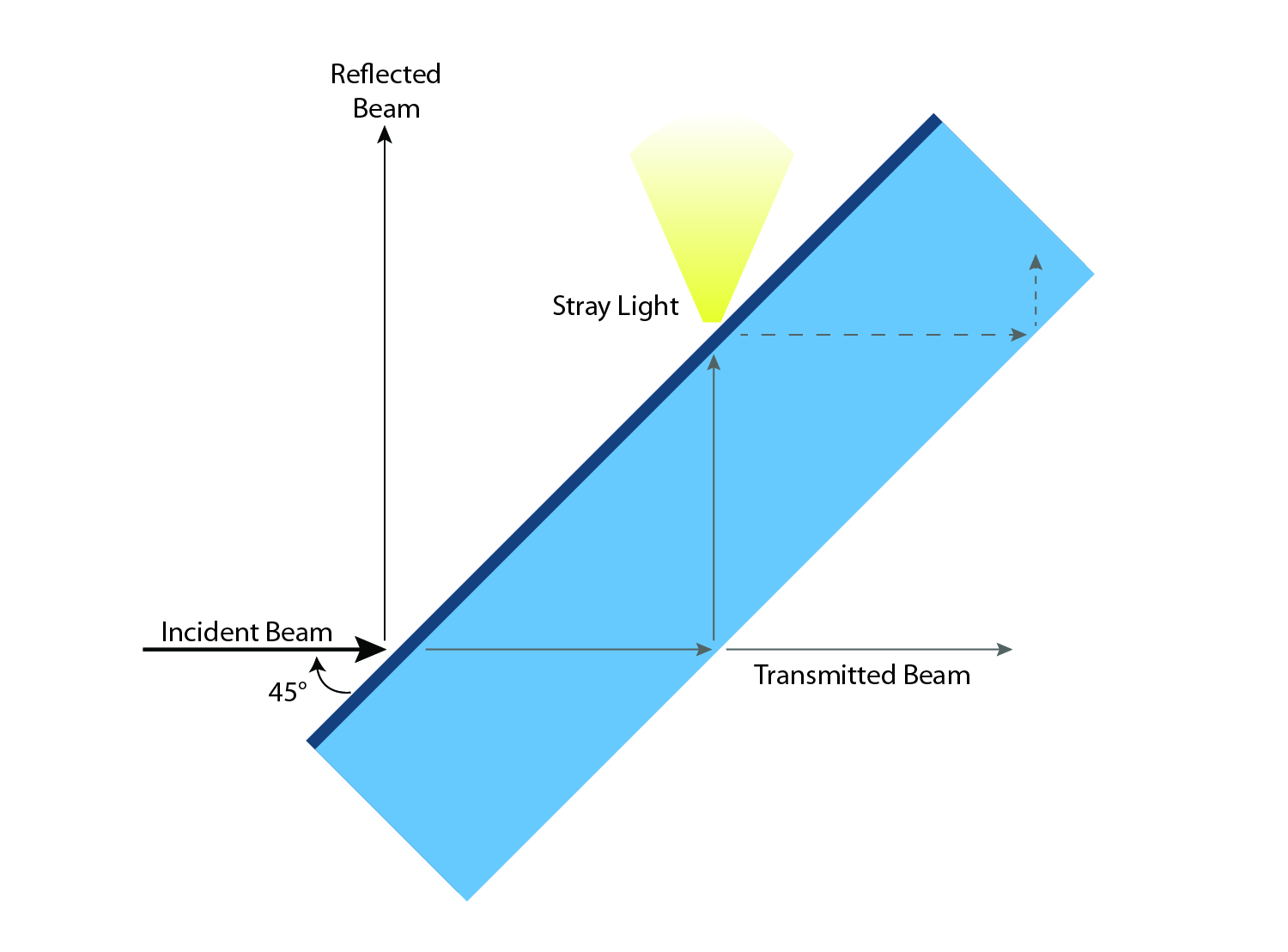

Development of high performance optical systems frequently requires the use of an interferometer to detect imperfections and ensure high precision performance. Most interferometers rely on beamsplitters as do other optical applications such as aeronautical and automotive heads up displays. However, an uncoated beamsplitter will often allow stray light to be reflected in addition to the beam reflecting off of the primary surface. To achieve the desired level of performance, beamsplitters are often used in conjunction with anti-reflective coatings to not only split a beam of light into two, but also to enhance the beamsplitter’s efficiency and prevent ghost reflections caused by stray light.

Anti-Reflective Coatings and Beamsplitters - A Synergetic Relationship

Topics: Optical Coating, Anti-Reflection Coatings

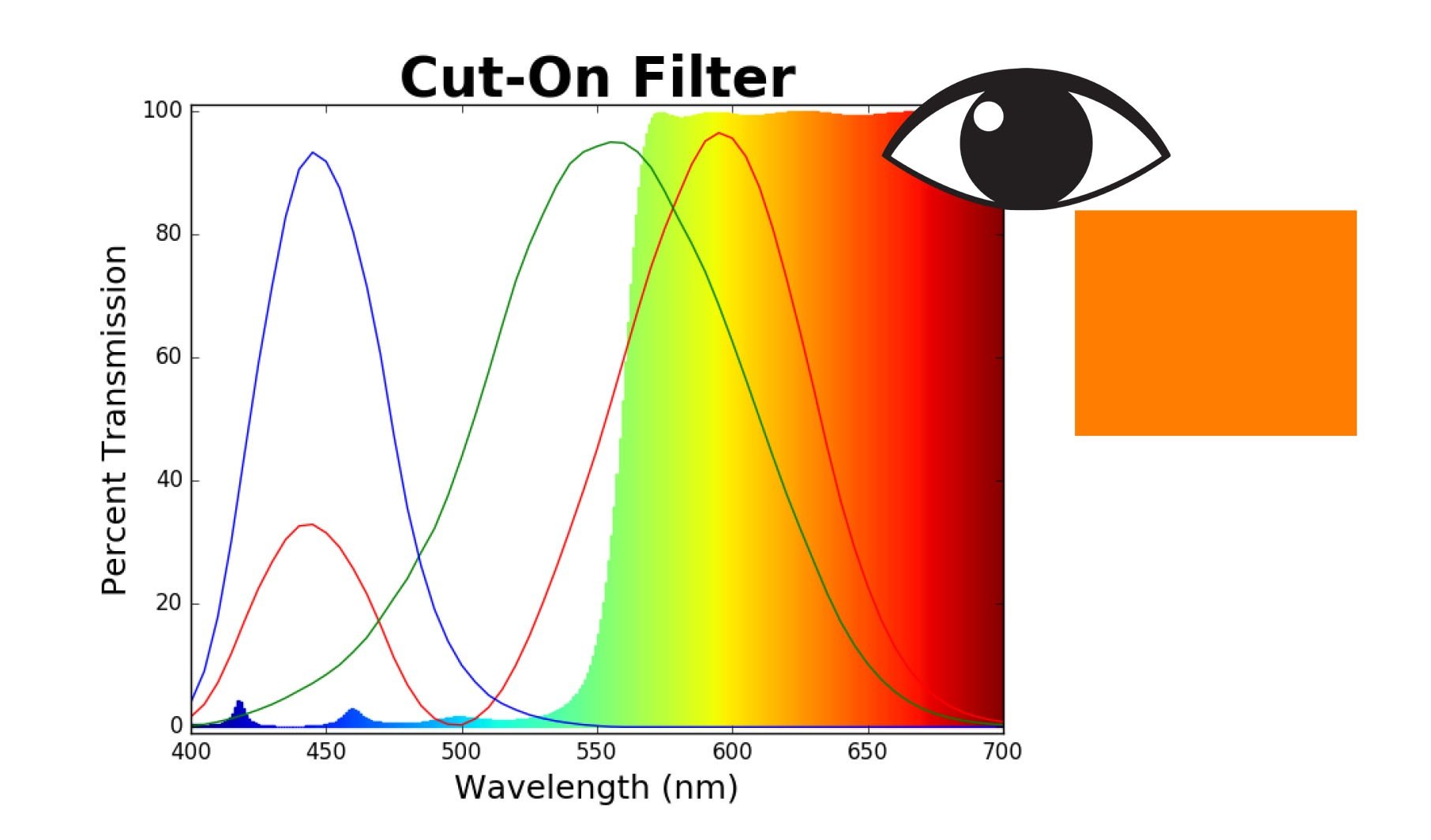

Color Matching through Optical Coating: Visualizing an Example Cut-on Filter

The performance of a cut-on optical filter is typically presented using the plot of the percentage transmission at each specified wavelength. The figure below demonstrates the combination of light that would be transmitted through a cut-on filter with the stopband and passband in the visible range. The red, green and blue curves are color matching functions designed to quantify the way the human eye perceives color. When the transmitted spectrum is combined with color matching functions, we can see that the light transmitted through the filter will appear to be orange colored.

Topics: Optical Filters, Color Matching

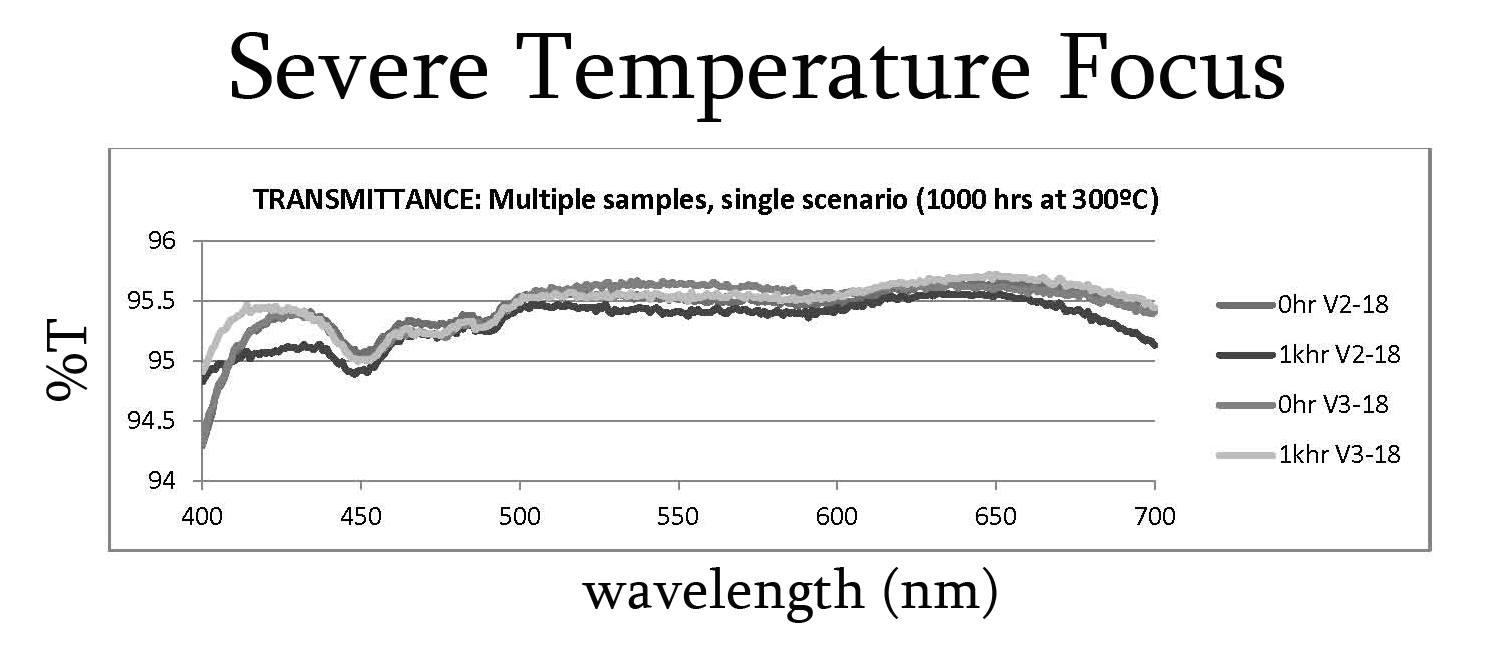

Environmental Durability Testing on Optical Coatings Glass for the Display Industry

Environmental durability testing is essential for optical coatings prone to degrading due to exposure to humidity, temperature changes, abrasion and exposure to chemicals. To ensure the durability of optical coatings, testing should be conducted to simulate maximum exposure to these variables. In the display industry, humidity and temperature are particularly relevant because the light from bulbs used in certain devices can create extremely high temperatures after prolonged usage. Any coatings used on optical components, regardless of the substrate, must withstand these conditions to avoid interfering with lens performance, and ultimately the performance of the entire product.

Topics: Anti-Reflection Coatings, Optical Coating Durability

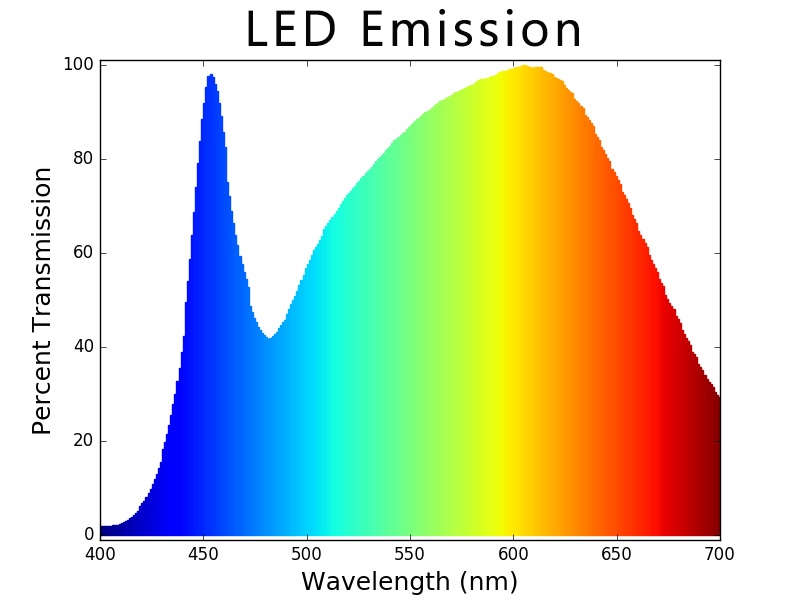

Common Uses of Optical Filters: An Example of LED Emission and Color Perception

A light source, whether natural or man-made, typically emits a broad spectrum of wavelengths, including ultraviolet and infrared. In some applications, this full spectrum is acceptable or even desired. In others, however, it may be necessary to limit the wavelengths passing from the light source. This is where optical filters come in.

Topics: Optical Coating, Optical Filters

Ongoing Optical Coating Education: VisiMax's Annual Training Day Focuses on Safety and Performance

Every year, VisiMax Technologies holds a "Training Day" for all employees. Though the company's expert staff has thorough experience, the company recognizes the value of continued optical coating education. Chris Murphy, VisiMax Vice President, explains why the company takes the time to devote 100% of a day to training on processes, equipment, and safety.

Topics: Optical Coating, Business Development

Expanding Optical Coating Knowledge: Utilizing Industry Experts and Best Practices to Ensure Peak Performance

In a complex industry that is constantly evolving, staying current on the latest developments is key to understanding customer needs and continuing to be a preferred partner in supply chains. As it is in other industries, continuous education is important to succeeding in optical coating. For VisiMax, investing in the skills and knowledge of its technical team leads to greater opportunities for the organization. This applies to the newest members of the team as well as seasoned thin film coating professionals.

Topics: Optical Coating, Business Development

VisiMax Technical Team to Attend Techcon 2017, a Technical Conference Held by the Society of Vacuum Coaters

April 29-May 4, VisiMax's technical team will attend Techcon, a technical conference hosted by the Society of Vacuum Coaters (SVC), the global source for learning, applying, and advancing vacuum coating, surface engineering, and related technologies.

Topics: Optical Coating, Business Development, Vacuum Coating

Filtering Light: Optical Filters Designed to Provide More Desirable Lighting

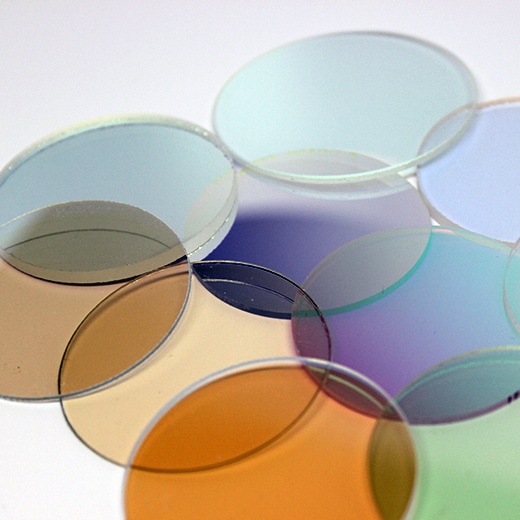

Optical filters are generally used to selectively transmit or reject a narrow wavelength band or a range of wavelengths. VisiMax can provide a variety of optical light filters; one area of application is filter coatings. VisiMax Process Color Filters selectively and accurately pass the light of a small range of colors while reflecting other colors. Our heat-resistant dichroic filter coating technology produces durable interference filters that render light with precise spectral control.

Topics: Optical Coating, Anti-Reflection Coatings

A Review of Photonics West 2017: The Perspectives of New and Experienced Optical Coaters

Photonics West attendees can nearly always expect a great show, but exactly what makes it great changes year after year. Sometimes it's the exhibitors' displays that wow, other years the classes and presentations get the attention, and the conversations with fellow attendees are always of interest to those looking to keep up with the latest industry trends.

Topics: Trends, Business Development

Reducing Transmission Loss with Anti-Reflection Coatings: The Benefits of VisiClear Coatings

As one of the most common types of optical coatings, anti-reflective coatings are typically used in various types of applications such as light fixtures, displays, and eyewear. Specifically, VisiClear Anti-Reflection Coatings from VisiMax are used in applications across a wide variety of industries and across the globe. One other notable application for anti-reflection coatings is Digital Light Projection (DLP) systems.

Topics: Capabilities, Anti-Reflection Coatings